BS 4504 Flange Supplier, Manufacturer in India

Unichem Steel & Alloy Pvt. Ltd. is a trusted Manufacturer, Exporter, and Supplier of a comprehensive range of BS 4504 Flange within the global industrial market. British Standard 4504 Circular Flange for Pipe, Valve, and Fitting, Specification for Steel Flanges. BS 4504 Flanges substantially agree with ISO 7005-1:1992 Flanges. BS 4504:1969 remains commonly used. There are minor differences in dimensions between the 2 versions. BS 4504 Flanges are circular flanges that are made from steel and gray or malleable forged iron. the dimensions of the flange range from DN 15 to DN 2000 and therefore the types differ as weld neck flanges threaded flanges, slip-on flanges, plate flanges, blind flanges, and so on. The BS 4504 PN16 Flanges have low-pressure capacities consistent with pressure number PN 16. There are flanges starting from PN6 to PN64. These flanges are often either forged or stamped during manufacture. the fabric grades used for the making of the BS 4504 Pipe Flanges vary consistent with ASTM A182. The Bs 4504 Forged Flange springs from one piece of the material so it’s stronger. There are different classes and dimensions to the various sorts of the DIN86029 PN10 BS 4504 Flanges. The BS 4504 PN6 Flange is used in power generation, oil and gas, and other general corrosive applications.

Largest Stockist of BS 4504 Flanges, BS 4504 Flange PN6-PN40, BS 4504 Forged Flange, BS 4504 Blind Flange, BS 4504 Plate Flange, BS 4504 Threaded Flange, BS 4504 Weld Neck Flange in Mumbai.

Most Trusted Exporters of BS 4504 Flanges in South Africa, Saudi Arabia, Spain, Kuwait, Singapore, Malaysia, UAE, Italy, Nigeria, Iraq, Thailand, Turkey, Vietnam, Oman, Qatar, Myanmar, Sri Lanka.

BS 4504 Flange Specifications

Specifications

ASTM A182, A 240, A105, A350, A694, A516 / ASME SA182, SB240, SA 105, SA350, SA694

Standards / Dimensions

ANSI B16.47, MSS SP44, ANSI B16.5, Series A & B, ASA, API-605, AWWA, B16.48, BS 10, BS4504, EN-1092, DIN.

Size & Thickness

½” (15 NB) to 48″ (1200NB)

Pressure Class

PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Class

150#, 300#, 400#, 600#, 900#, 1500#, 2500#.

Forms

BS 4504

Flange Face Type

Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

Connection Type

Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large Tongue & Groove, Small Tongue & Groove

BS 4504 Flange Dimensions

BS 4504 Standard Flange Facing Dimensions

| DN |

A mm |

Face Dimensions | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN 2.5 | PN 6 | PN 10 | PN 16 | PN 25 | PN 40 |

B mm |

C mm |

D mm |

E mm |

a mm |

b mm |

c mm |

d mm | αmm |

e mm |

|

| 10 | 35 | 35 | 40 | 40 | 40 | 40 | 34 | 35 | 24 | 23 | 2 | 4 | 3 | 2 | – | 5 |

| 15 | 40 | 40 | 45 | 45 | 45 | 45 | 39 | 40 | 29 | 28 | 2 | 4 | 3 | 2 | – | 5 |

| 20 | 50 | 50 | 58 | 58 | 58 | 58 | 50 | 51 | 36 | 35 | 2 | 4 | 3 | 2 | 41°16′ | 5 |

| 25 | 60 | 60 | 68 | 68 | 68 | 68 | 57 | 58 | 43 | 42 | 2 | 4 | 3 | 2 | 41°16′ | 5 |

| 32 | 70 | 70 | 78 | 78 | 78 | 78 | 65 | 66 | 51 | 50 | 2 | 4 | 3 | 2 | 41°16′ | 5 |

| 40 | 80 | 80 | 88 | 88 | 88 | 88 | 75 | 76 | 61 | 60 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 50 | 90 | 90 | 102 | 102 | 102 | 102 | 87 | 88 | 73 | 72 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 65 | 110 | 110 | 122 | 122 | 122 | 122 | 109 | 110 | 95 | 94 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 80 | 128 | 128 | 138 | 138 | 138 | 138 | 120 | 121 | 106 | 105 | 3 | 4 | 3 | 2 | 41°16′ | 5 |

| 100 | 148 | 148 | 158 | 158 | 162 | 162 | 149 | 150 | 129 | 128 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 125 | 178 | 178 | 188 | 188 | 188 | 188 | 175 | 176 | 155 | 154 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 150 | 202 | 202 | 212 | 212 | 218 | 218 | 203 | 204 | 183 | 182 |

3 |

4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 200 | 258 | 258 | 268 | 268 | 278 | 285 | 259 | 260 | 239 | 238 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 250 | 312 | 312 | 320 | 320 | 335 | 345 | 312 | 313 | 292 | 291 | 3 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 300 | 365 | 365 | 370 | 378 | 395 | 410 | 363 | 364 | 343 | 342 | 4 | 4.5 | 3.5 | 2.5 | 32°15′ | 6 |

| 350 | 415 | 415 | 430 | 438 | 450 | 465 | 421 | 422 | 395 | 394 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 400 | 465 | 465 | 482 | 490 | 505 | 535 | 473 | 474 | 447 | 446 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 450 | 520 | 520 | 532 | 550 | 555 | 560 | 523 | 524 | 497 | 496 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 500 | 570 | 570 | 585 | 610 | 615 | 615 | 575 | 576 | 549 | 548 | 4 | 5 | 4 | 3 | 27°24′ | 7 |

| 600 | 670 | 670 | 685 | 725 | 720 | 735 | 675 | 676 | 649 | 648 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 700 | 775 | 775 | 800 | 795 | 820 | – | 777 | 778 | 751 | 750 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 800 | 880 | 880 | 905 | 900 | 930 | – | 882 | 883 | 856 | 855 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 900 | 980 | 980 | 1005 | 1000 | 1030 | – | 987 | 988 | 961 | 960 | 5 | 5 | 4 | 3 | 27°24′ | 7 |

| 1000 | 1080 | 1080 | 1110 | 1115 | 1140 | – | 1092 | 1094 | 1062 | 1060 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1200 | 1280 | 1295 | 1330 | 1330 | 1350 | – | 1292 | 1294 | 1262 | 1260 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1400 | 1480 | 1510 | 1535 | 1530 | 1560 | – | 1492 | 1494 | 1462 | 1460 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1600 | 1690 | 1710 | 1760 | 1750 | 1780 | – | 1692 | 1694 | 1662 | 1660 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 1800 | 1890 | 1920 | 1960 | 1950 | 1985 | – | 1982 | 1894 | 1862 | 1860 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

| 2000 | 2090 | 2125 | 2170 | 2150 | 2210 | – | 2092 | 2094 | 2062 | 2060 | 5 | 6 | 5 | 4 | 28°39′ | 8 |

BS 4504 Standard Flange Drilling Details and Dimensions.

| DN | PN | A | B | C | Bolt Holes | |

|---|---|---|---|---|---|---|

| mm | mm | mm | No. | Bolt size | ||

| 10 | 2.5 & 6 | 75 | 50 | 11 | 4 | M10 |

| 10,16, | 90 | 60 | 14 | 4 | M12 | |

| 15 | 2.5 & 6 | 80 | 55 | 11 | 4 | M10 |

| 10 & 16 | 95 | 65 | 14 | 4 | M12 | |

| 25 & 40 | 95 | 65 | 14 | 4 | M12 | |

| 20 | 2.5 & 6 | 90 | 65 | 11 | 4 | M10 |

| 10 & 16 | 105 | 75 | 14 | 4 | M12 | |

| 25 &40 | 105 | 75 | 14 | 4 | M12 | |

| 25 | 2.5 & 6 | 100 | 75 | 11 | 4 | M10 |

| 10 & 16 | 115 | 85 | 14 | 4 | M12 | |

| 25&40 | 115 | 85 | 14 | 4 | M12 | |

| 32 | 2.5 & 6 | 120 | 90 | 14 | 4 | M12 |

| 10 & 16 | 140 | 100 | 18 | 4 | M16 | |

| 25 & 40 | 140 | 100 | 18 | 4 | M16 | |

| 40 | 2.5 & 6 | 130 | 100 | 14 | 4 | M12 |

| 10 & 16 | 150 | 110 | 18 | 4 | M16 | |

| 25 &40 | 150 | 110 | 18 | 4 | M16 | |

| 50 | 2.5 & 6 | 140 | 110 | 14 | 4 | M12 |

| 10 & 16 | 165 | 125 | 18 | 4 | M16 | |

| 25 &40 | 165 | 125 | 18 | 4 | M16 | |

| 65 | 2.5 & 6 | 160 | 130 | 14 | 4 | M12 |

| 10 & 16 | 185 | 145 | 18 | 4/8 | M16 | |

| 25 & 40 | 185 | 145 | 18 | 8 | M16 | |

| 80 | 2.5 & 6 | 190 | 150 | 18 | 4 | M16 |

| 10 & 16 | 200 | 160 | 18 | 8 | M16 | |

| 25 &40 | 200 | 160 | 18 | 8 | M16 | |

| 100 | 2.5 & 6 | 210 | 170 | 18 | 4 | M16 |

| 10 & 16 | 220 | 180 | 18 | 8 | M16 | |

| 25 &40 | 235 | 190 | 22 | 8 | M20 | |

| 125 | 2.5 & 6 | 240 | 200 | 18 | 8 | M16 |

| 10 & 16 | 250 | 210 | 18 | 8 | M16 | |

| 25 & 40 | 270 | 220 | 26 | 8 | M24 | |

| 150 | 2.5 & 6 | 265 | 225 | 18 | 8 | M16 |

| 10 & 16 | 285 | 240 | 22 | 8 | M20 | |

| 25 & 40 | 300 | 250 | 26 | 8 | M24 | |

| 200 | 2.5 & 6 | 320 | 280 | 18 | 8 | M16 |

| 10 & 16 | 340 | 295 | 22 | 8/12 | M20 | |

| 25 | 360 | 310 | 26 | 12 | M24 | |

| 40 | 375 | 320 | 30 | 12 | M27 | |

| 250 | 2.5 & 6 | 375 | 335 | 18 | 12 | M16 |

| 10 | 395 | 350 | 22 | 12 | M20 | |

| 16 | 405 | 355 | 26 | 12 | M24 | |

| 25 | 425 | 370 | 30 | 12 | M27 | |

| 40 | 450 | 385 | 33 | 12 | M30 | |

| 300 | 2.5 & 6 | 440 | 395 | 22 | 12 | M20 |

| 10 | 445 | 400 | 22 | 12 | M20 | |

| 16 | 460 | 410 | 26 | 12 | M24 | |

| 25 | 485 | 430 | 30 | 16 | M27 | |

| 40 | 515 | 450 | 33 | 16 | M30 | |

BS 4504 Standard Code 101 Plate Flange Dimensions

| DN | PN | A mm | B mm | C mm |

|---|---|---|---|---|

| 10 | 2.5, 6 | 75 | 12 | 18 |

| 10 &16 | 90 | 14 | ||

| 25 & 40 | 90 | 14 | ||

| 15 | 2.5 & 6 | 80 | 12 | 22 |

| 10 &16 | 95 | 14 | ||

| 25 & 40 | 95 | 14 | ||

| 20 | 2.5 & 6 | 90 | 14 | 27.5 |

| 10 &16 | 105 | 16 | ||

| 25 & 40 | 105 | 16 | ||

| 25 | 2.5 & 6 | 100 | 14 | 34.5 |

| 10 &16 | 115 | 16 | ||

| 25 & 40 | 115 | 16 | ||

| 32 | 2.5 & 6 | 120 | 16 | 43.5 |

| 10 &16 | 140 | 18 | ||

| 25 & 40 | 140 | 18 | ||

| 40 | 2.5 & 6 | 130 | 16 | 49.5 |

| 10 &16 | 150 | 18 | ||

| 25 & 40 | 150 | 18 | ||

| 50 | 2.5 & 6 | 140 | 16 | 61.5 |

| 10 & 16 | 165 | 20 | ||

| 25 & 40 | 165 | 20 | ||

| 65 | 2.5 & 6 | 160 | 16 | 77.5 |

| 10 & 16 | 185 | 20 | ||

| 25 & 40 | 185 | 22 | ||

| 80 | 2.5 & 6 | 190 | 18 | 90.5 |

| 10 &16 | 200 | 20 | ||

| 25 & 40 | 200 | 24 | ||

| 100 | 2.5 & 6 | 210 | 18 | 116 |

| 10 &16 | 220 | 22 | ||

| 25 & 40 | 235 | 26 | ||

| 125 | 2.5 & 6 | 240 | 20 | 141.5 |

| 10 & 16 | 250 | 22 | ||

| 25 & 40 | 270 | 28 | ||

| 150 | 2.5 & 6 | 265 | 20 | 170.5 |

| 10 & 16 | 285 | 24 | ||

| 25 & 40 | 300 | 30 | ||

| 200 | 2.5 & 6 | 320 | 22 | 221.5 |

| 10 &16 | 340 | 24 | ||

| 25 | 360 | 32 | ||

| 40 | 375 | 36 | ||

| 250 | 2.5 & 6 | 375 | 24 | 276.5 |

| 10 | 395 | 26 | ||

| 16 | 405 | 29 | ||

| 25 | 425 | 35 | ||

| 40 | 450 | 42 | ||

| 300 | 2.5 & 6 | 440 | 24 | 327.5 |

| 10 | 445 | 26 | ||

| 16 | 460 | 32 | ||

| 25 | 485 | 38 | ||

| 40 | 515 | 48 | ||

| 350 | 2.5 & 6 | 490 | 26 | 359.5 |

| 10 | 505 | 28 | ||

| 16 | 520 | 35 | 359 | |

| 25 | 555 | 42 | 359.5 | |

| 40 | 580 | 54 | ||

| 400 | 2.5 & 6 | 540 | 28 | 411 |

| 10 | 565 | 32 | ||

| 16 | 580 | 38 | ||

| 25 | 620 | 46 | ||

| 40 | 660 | 60 | ||

| 450 | 2.5 & 6 | 595 | 30 | 462 |

| 10 | 615 | 36 | ||

| 16 | 640 | 42 | ||

| 25 | 670 | 50 | ||

| 40 | 685 | 66 | ||

| 500 | 2.5 & 6 | 645 | 30 | 513.5 |

| 10 | 670 | 38 | ||

| 16 | 715 | 46 | ||

| 25 | 730 | 56 | ||

| 40 | 755 | 72 | ||

| 600 | 2.5 & 6 | 755 | 32 | 616.5 |

| 10 | 780 | 42 | ||

| 16 | 840 | 52 | ||

| 25 | 845 | 68 | ||

| 40 | 890 | 84 | ||

| 700 | 2.5 | 860 | 36 | To be specifiedby purchaser |

| 800 | 2.5 | 975 | 38 | |

| 900 | 2.5 | 1075 | 40 | |

| 1000 | 2.5 | 1175 | 42 | |

| 1200 | 2.5 | 1375 | 44 | |

| 1400 | 2.5 | 1575 | 48 | |

| 1600 | 2.5 | 1790 | 51 | |

| 1800 | 2.5 | 1990 | 54 | |

| 2000 | 2.5 | 2190 | 58 |

BS 4504 Standard Code 111 Weld Neck Flange Dimensions

| DN | PN | A mm | B mm | C mm | D mm | E mm | F mm | G mm | H mm |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 2.5,6 | 75 | 17.2 | 12 | 28 | 6 | 26 | 3 | 1.8 |

| 10 | 90 | 14 | 35 | 28 | 1.8 | ||||

| 16 | 90 | 14 | 35 | 28 | 1.8 | ||||

| 25 | 90 | 16 | 35 | 28 | 1.8 | ||||

| 40 | 90 | 16 | 35 | 28 | 1.8 | ||||

| 15 | 2.5,6 | 80 | 21.3 | 12 | 30 | 6 | 30 | 3 | 2 |

| 10 | 95 | 14 | 35 | 32 | 2 | ||||

| 16 | 95 | 14 | 35 | 32 | 2 | ||||

| 25 | 95 | 16 | 38 | 32 | 2 | ||||

| 40 | 95 | 16 | 38 | 32 | 2 | ||||

| 20 | 2.5,6 | 90 | 26.9 | 14 | 32 | 6 | 38 | 4 | 2.3 |

| 10 | 105 | 16 | 38 | 39 | 2.3 | ||||

| 16 | 105 | 16 | 38 | 39 | 2.3 | ||||

| 25 | 105 | 18 | 40 | 40 | 2.3 | ||||

| 40 | 105 | 18 | 40 | 40 | 2.3 | ||||

| 25 | 2.5,6 | 100 | 33.7 | 14 | 35 | 6 | 42 | 4 | 2.6 |

| 10 | 115 | 16 | 38 | 46 | 2.6 | ||||

| 16 | 115 | 16 | 38 | 46 | 2.6 | ||||

| 25 | 115 | 18 | 40 | 46 | 2.6 | ||||

| 40 | 115 | 18 | 40 | 46 | 2.6 | ||||

| 32 | 2.5,6 | 120 | 42.4 | 14 | 35 | 6 | 55 | 5 | 2.6 |

| 10 | 140 | 16 | 40 | 56 | 2.6 | ||||

| 16 | 140 | 16 | 40 | 56 | 2.6 | ||||

| 25 | 140 | 18 | 42 | 56 | 2.6 | ||||

| 40 | 140 | 18 | 42 | 56 | 2.6 | ||||

| 40 | 2.5,6 | 130 | 48.3 | 14 | 38 | 7 | 62 | 5 | 2.6 |

| 10 | 150 | 16 | 42 | 64 | 2.6 | ||||

| 16 | 150 | 16 | 42 | 64 | 2.6 | ||||

| 25 | 150 | 18 | 45 | 64 | 2.6 | ||||

| 40 | 150 | 18 | 45 | 64 | 2.6 | ||||

| 50 | 2.5,6 | 140 | 60.3 | 14 | 38 | 8 | 74 | 5 | 2.9 |

| 10 | 165 | 18 | 45 | 74 | 2.9 | ||||

| 16 | 165 | 18 | 45 | 74 | 2.9 | ||||

| 25 | 165 | 20 | 48 | 74 | 2.9 | ||||

| 40 | 165 | 20 | 48 | 74 | 2.9 | ||||

| 65 | 2.5,6 | 160 | 76.1 | 14 | 38 | 9 | 88 | 6 | 2.9 |

| 10 | 185 | 18 | 45 | 10 | 92 | 2.9 | |||

| 16 | 185 | 18 | 45 | 92 | 2.9 | ||||

| 25 | 185 | 22 | 52 | 92 | 2.9 | ||||

| 40 | 185 | 22 | 52 | 92 | 2.9 | ||||

| 80 | 2.5,6 | 190 | 88.9 | 16 | 42 | 10 | 102 | 6 | 3.2 |

| 10 | 200 | 20 | 50 | 110 | 3.2 | ||||

| 16 | 200 | 20 | 50 | 12 | 110 | 3.2 | |||

| 25 | 200 | 24 | 58 | 110 | 3.2 | ||||

| 40 | 200 | 24 | 58 | 110 | 3.2 |

BS 4504 Standard Code 112 Slip On Flange Dimensions

| DN | PN | A mm | B mm | C mm | D mm | E mm | F mm |

|---|---|---|---|---|---|---|---|

| 10 | 6 | 75 | 18 | 12 | 20 | 25 | 3 |

| 10 &16 | 90 | 14 | 20 | 30 | |||

| 25 & 40 | 90 | 16 | 22 | 30 | |||

| 15 | 6 | 80 | 22 | 12 | 20 | 30 | 3 |

| 10 &16 | 95 | 14 | 20 | 35 | |||

| 25 & 40 | 95 | 16 | 22 | 35 | |||

| 20 | 6 | 90 | 27.5 | 14 | 24 | 40 | 4 |

| 10 &16 | 105 | 16 | 24 | 45 | |||

| 25 & 40 | 105 | 18 | 26 | 45 | |||

| 25 | 6 | 100 | 34.5 | 14 | 24 | 50 | 4 |

| 10 &16 | 115 | 16 | 24 | 52 | |||

| 25 & 40 | 115 | 18 | 28 | 52 | |||

| 32 | 6 | 120 | 43.5 | 14 | 26 | 60 | 5 |

| 10 &16 | 140 | 16 | 26 | 60 | |||

| 25 & 40 | 140 | 18 | 30 | 60 | |||

| 40 | 6 | 130 | 49.5 | 14 | 26 | 70 | 5 |

| 10 &16 | 150 | 16 | 26 | 70 | |||

| 25 & 40 | 150 | 18 | 32 | 70 | |||

| 50 | 6 | 140 | 61.5 | 14 | 28 | 80 | 5 |

| 10 & 16 | 165 | 18 | 28 | 84 | |||

| 25 & 40 | 165 | 20 | 34 | 84 | |||

| 65 | 6 | 160 | 77.5 | 14 | 32 | 100 | 6 |

| 10 & 16 | 185 | 18 | 32 | 104 | |||

| 25 & 40 | 185 | 22 | 38 | 104 | |||

| 80 | 6 | 190 | 90.5 | 16 | 34 | 110 | 6 |

| 10 &16 | 200 | 20 | 34 | 118 | |||

| 25&40 | 200 | 24 | 40 | 118 | |||

| 100 | 6 | 210 | 116 | 16 | 40 | 130 | 6 |

| 10 &16 | 220 | 20 | 40 | 140 | |||

| 25&40 | 235 | 24 | 44 | 145 | |||

| 125 | 6 | 240 | 141.5 | 18 | 44 | 160 | 6 |

| 10 & 16 | 250 | 22 | 44 | 168 | |||

| 25 & 40 | 270 | 26 | 48 | 170 | |||

| 150 | 6 | 265 | 170.5 | 18 | 44 | 185 | 8 |

| 10 & 16 | 285 | 22 | 44 | 195 | |||

| 25 & 40 | 300 | 28 | 75 | 190 |

| DN | PN | A mm | B mm | C mm | D mm | E mm | F mm |

| 200 | 6 | 320 | 221.5 | 20 | 44 | 240 | 8 |

| 10 &16 | 340 | 24 | 44 | 246 | |||

| 25 | 360 | 30 | 52 | 256 | |||

| 40 | 375 | 34 | 52 | 260 | |||

| 250 | 6 | 375 | 276.5 | 22 | 44 | 295 | 10 |

| 10 | 395 | 26 | 46 | 298 | |||

| 16 | 405 | 26 | 46 | 298 | |||

| 25 | 425 | 32 | 60 | 310 | |||

| 40 | 450 | 38 | 60 | 312 | |||

| 300 | 6 | 440 | 327.5 | 22 | 44 | 355 | 10 |

| 10 | 445 | 26 | 46 | 350 | |||

| 16 | 460 | 28 | 46 | 350 | |||

| 25 | 485 | 34 | 67 | 364 | |||

| 40 | 515 | 42 | 67 | 380 | |||

| 350 | 10 | 505 | 359.5 | 26 | 53 | 400 | 10 |

| 16 | 520 | 359 | 30 | 57 | 400 | ||

| 25 | 555 | 359.5 | 38 | 72 | 418 | ||

| 40 | 580 | 46 | 72 | 424 | |||

| 400 | 10 | 565 | 411 | 26 | 57 | 456 | 10 |

| 16 | 580 | 32 | 63 | 456 | |||

| 25 | 620 | 40 | 78 | 472 | |||

| 40 | 660 | 50 | 78 | 478 | |||

| 450 | 10 | 615 | 462 | 28 | 63 | 502 | 12 |

| 16 | 640 | 34 | 68 | 502 | |||

| 25 | 670 | 42 | 84 | 520 | |||

| 40 | 685 | 50 | 84 | 522 | |||

| 500 | 10 | 670 | 513.5 | 28 | 67 | 559 | 12 |

| 16 | 715 | 34 | 73 | 559 | |||

| 25 | 730 | 44 | 90 | 580 | |||

| 40 | 755 | 52 | 90 | 576 | |||

| 600 | 10 | 780 | 616.5 | 28 | 75 | 658 | 12 |

| 16 | 840 | 36 | 83 | 658 | |||

| 25 | 845 | 46 | 100 | 684 | |||

| 40 | 890 | 60 | 100 | 686 |

BS 4504 Code 113 Threaded Flange Dimensions in mm

| DN | PN | A mm | B mm | C mm | D mm | E mm |

|---|---|---|---|---|---|---|

| 10 | 6 | 75 | 25 | 12 | 20 | 3 |

| 16 | 90 | 30 | 14 | 20 | ||

| 40 | 90 | 30 | 16 | 22 | ||

| 15 | 6 | 80 | 30 | 12 | 20 | 3 |

| 16 | 95 | 35 | 14 | 20 | ||

| 40 | 95 | 35 | 16 | 22 | ||

| 20 | 6 | 90 | 40 | 14 | 24 | 4 |

| 16 | 105 | 45 | 16 | 24 | ||

| 40 | 105 | 45 | 18 | 26 | ||

| 25 | 6 | 100 | 50 | 14 | 24 | 4 |

| 16 | 115 | 52 | 16 | 24 | ||

| 40 | 115 | 52 | 18 | 28 | ||

| 32 | 6 | 120 | 60 | 14 | 26 | 5 |

| 16 | 140 | 60 | 16 | 26 | ||

| 40 | 140 | 60 | 18 | 30 | ||

| 40 | 6 | 130 | 70 | 14 | 26 | 5 |

| 16 | 150 | 70 | 16 | 26 | ||

| 40 | 150 | 70 | 18 | 32 | ||

| 50 | 6 | 140 | 80 | 14 | 28 | 5 |

| 16 | 165 | 84 | 18 | 28 | ||

| 40 | 165 | 84 | 20 | 34 | ||

| 65 | 6 | 160 | 100 | 14 | 32 | 6 |

| 16 | 185 | 104 | 18 | 32 | ||

| 40 | 185 | 104 | 22 | 38 | ||

| 80 | 6 | 190 | 110 | 16 | 34 | 6 |

| 16 | 200 | 118 | 20 | 34 | ||

| 40 | 200 | 118 | 24 | 40 | ||

| 100 | 6 | 210 | 130 | 16 | 40 | 6 |

| 16 | 220 | 140 | 20 | 40 | ||

| 40 | 235 | 145 | 24 | 44 |

| DN | PN | A mm | B mm | C mm | D mm | E mm |

| 125 | 6 | 240 | 160 | 18 | 44 | 6 |

| 16 | 250 | 168 | 22 | 44 | ||

| 40 | 270 | 170 | 26 | 48 | ||

| 150 | 6 | 265 | 185 | 18 | 44 | 8 |

| 16 | 285 | 195 | 22 | 44 | ||

| 40 | 300 | 200 | 28 | 52 | ||

| 200 | 6 | 320 | 240 | 20 | 44 | 8 |

| 16 | 340 | 246 | 24 | 44 | ||

| 40 | 375 | 260 | 34 | 52 | ||

| 250 | 6 | 375 | 295 | 22 | 44 | 10 |

| 16 | 405 | 298 | 26 | 46 | ||

| 40 | 450 | 312 | 38 | 60 | ||

| 300 | 6 | 440 | 355 | 22 | 44 | 10 |

| 16 | 460 | 350 | 28 | 46 | ||

| 40 | 515 | 380 | 42 | 67 | ||

| 350 | 16 | 520 | 400 | 30 | 57 | 10 |

| 40 | 580 | 424 | 46 | 72 | ||

| 400 | 16 | 580 | 456 | 32 | 63 | 10 |

| 40 | 660 | 478 | 50 | 78 | ||

| 450 | 16 | 640 | 502 | 34 | 68 | 12 |

| 40 | 685 | 522 | 50 | 84 | ||

| 500 | 16 | 715 | 559 | 34 | 73 | 12 |

| 40 | 755 | 576 | 52 | 90 | ||

| 600 | 16 | 840 | 658 | 36 | 83 | 12 |

| 40 | 890 | 686 | 60 | 100 | ||

| 700 | 16 | 910 | 760 | 36 | 83 | 12 |

| 800 | 16 | 1025 | 864 | 38 | 90 | 12 |

| 900 | 16 | 1125 | 968 | 40 | 94 | 12 |

| 1000 | 16 | 1255 | 1072 | 42 | 100 | 12 |

BS 4504 Code 105 Blind Flange Dimensions

| DN | PN | A mm | B mm | C mm |

|---|---|---|---|---|

| 10 | 2.5, 6 | 75 | 12 | – |

| 10 &16 | 90 | 14 | – | |

| 25 & 40 | 90 | 16 | – | |

| 15 | 2.5 & 6 | 80 | 12 | – |

| 10 &16 | 95 | 14 | – | |

| 25 & 40 | 95 | 16 | – | |

| 20 | 2.5 & 6 | 90 | 14 | – |

| 10 &16 | 105 | 16 | – | |

| 25 & 40 | 105 | 18 | – | |

| 25 | 2.5 & 6 | 100 | 14 | – |

| 10 &16 | 115 | 16 | – | |

| 25 & 40 | 115 | 18 | – | |

| 32 | 2.5 & 6 | 120 | 14 | – |

| 10 &16 | 140 | 16 | – | |

| 25 & 40 | 140 | 18 | – | |

| 40 | 2.5 & 6 | 130 | 14 | – |

| 10 &16 | 150 | 16 | – | |

| 25 & 40 | 150 | 18 | – | |

| 50 | 2.5 & 6 | 140 | 14 | – |

| 10 & 16 | 165 | 18 | – | |

| 25 & 40 | 165 | 20 | – | |

| 65 | 2.5 & 6 | 160 | 14 | 55 |

| 10 & 16 | 185 | 18 | 55 | |

| 25 & 40 | 185 | 22 | 55 | |

| 80 | 2.5 & 6 | 190 | 16 | 70 |

| 10 &16 | 200 | 20 | 70 | |

| 25&40 | 200 | 24 | 70 | |

| 100 | 2.5 & 6 | 210 | 16 | 90 |

| 10 &16 | 220 | 20 | 90 | |

| 25&40 | 235 | 24 | 90 | |

| 125 | 2.5 & 6 | 240 | 18 | 115 |

| 10 & 16 | 250 | 22 | 115 | |

| 25 & 40 | 270 | 26 | 115 | |

| 150 | 2.5 & 6 | 265 | 18 | 140 |

| 10 & 16 | 285 | 22 | 140 | |

| 25 & 40 | 300 | 28 | 140 | |

| 200 | 2.5 & 6 | 320 | 20 | 190 |

| 10 &16 | 340 | 24 | 190 | |

| 25 | 360 | 30 | 190 | |

| 40 | 375 | 34 | 190 | |

| 250 | 2.5 & 6 | 375 | 22 | 235 |

| 10 | 395 | 26 | 235 | |

| 16 | 405 | 26 | 235 | |

| 25 | 425 | 32 | 235 | |

| 40 | 450 | 38 | 235 |

| DN | PN | A mm | B mm | C mm |

| 300 | 2.5 & 6 | 440 | 22 | 285 |

| 10 | 445 | 26 | 285 | |

| 16 | 460 | 28 | 285 | |

| 25 | 485 | 34 | 285 | |

| 40 | 515 | 42 | 285 | |

| 350 | 2.5 & 6 | 490 | 22 | 325 |

| 10 | 505 | 26 | 325 | |

| 16 | 520 | 30 | 325 | |

| 25 | 555 | 38 | 325 | |

| 40 | 580 | 46 | 325 | |

| 400 | 2.5 & 6 | 540 | 22 | 375 |

| 10 | 565 | 26 | 375 | |

| 16 | 580 | 32 | 375 | |

| 25 | 620 | 40 | 375 | |

| 40 | 660 | 50 | 375 | |

| 450 | 2.5 & 6 | 595 | 24 | 425 |

| 10 | 615 | 28 | 425 | |

| 16 | 640 | 34 | 425 | |

| 25 | 670 | 42 | 425 | |

| 40 | 685 | 54 | 425 | |

| 500 | 2.5 & 6 | 645 | 24 | 475 |

| 10 | 670 | 28 | 475 | |

| 16 | 715 | 36 | 475 | |

| 25 | 730 | 45 | 475 | |

| 40 | 755 | 56 | 475 | |

| 600 | 2.5 & 6 | 755 | 34 | 575 |

| 10 | 780 | 34 | 575 | |

| 16 | 840 | 44 | 575 | |

| 25 | 845 | 54 | 575 | |

| 40 | 890 | 70 | 575 | |

| 700 | 2.5 | 860 | 36 | – |

| 6 | 860 | 38 | – | |

| 10 | 895 | 38 | 670 | |

| 16 | 910 | 48 | 670 | |

| 800 | 2.5 | 975 | 38 | – |

| 6 | 975 | 42 | – | |

| 10 | 1015 | 42 | 770 | |

| 16 | 1025 | 52 | 770 | |

| 900 | 2.5 | 1075 | 40 | – |

| 6 | 1075 | 46 | – | |

| 10 | 1115 | 46 | 860 | |

| 16 | 1125 | 58 | 860 | |

| 1000 | 2.5 | 1175 | 42 | – |

| 6 | 1175 | 52 | – | |

| 10 | 1230 | 52 | 960 | |

| 16 | 1255 | 64 | 960 | |

| 1200 | 2.5 | 1375 | 44 | – |

| 6 | 1405 | 60 | – | |

| 10 | 1455 | 60 | 1160 | |

| 16 | 1485 | 76 | 1160 | |

| 1400 | 2.5 | 1575 | 48 | – |

| 6 | 1630 | 68 | – | |

| 1600 | 2.5 | 1790 | 51 | – |

| 6 | 1830 | 76 | – | |

| 1800 | 2.5 | 1990 | 54 | – |

| 6 | 2045 | 84 | – | |

| 2000 | 2.5 | 2190 | 58 | – |

| 6 | 2265 | 92 | – |

BS 4504 Standard Flanges Type code, PN range and Marking Requirements

|

Code No. |

Description |

PN Range |

DN Range |

|

101 |

Plate flange for welding(see page 8-65) |

PN 2.5 |

DN 10 to DN 2000 |

|

PN 6, 10, 16, 25, 40 |

DN 10 to DN 600 |

||

|

102 |

Loose plate flange with weld-on plate collar or for lapped pipe end (Weld-on plate collar = Code 1321 Lapped pipe end = Code 1331) |

PN 6, 10, 16, 25, 40 |

DN 10 to DN 600 |

|

104 |

Loose plate flange with weld-neck collar (Weldneck collar = Code 1341) |

PN 6, 10, 16, 25, 40 |

DN 10 to DN 600 |

|

PN 2.5, 6 |

DN 10 to DN 2000 |

||

|

105 |

Blank flange (see page 8-70) |

PN 10, 16 |

DN 10 to DN 1200 |

|

PN 25, 40 |

DN 10 to DN 600 |

||

|

PN 2.5, 6, 10, 16 |

DN 10 to DN 20002 |

||

|

111 |

Weld-neck flange (see page 8-66) |

PN 25 |

DN 10 to DN 1000 |

|

PN 40 |

DN 10 to DN 600 |

||

|

112 |

Hubbed slip-on flange for welding(see page 8-68) |

PN 6 |

DN 10 to DN 300 |

|

PN 10, 16, 25, 40 |

DN 10 to DN 600 |

||

|

113 |

Hubbed threaded flange (see page 8-69) |

PN 6, 10, 16, 25, 40 |

DN 10 to DN 150 |

|

121 |

Integral flange |

PN 6, 10, 16, 25 |

DN 10 to DN 2000 |

|

PN 40 |

DN 10 to DN 600 |

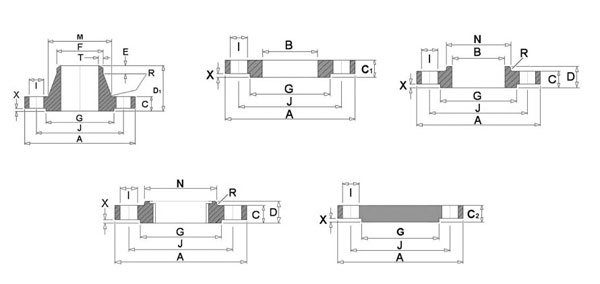

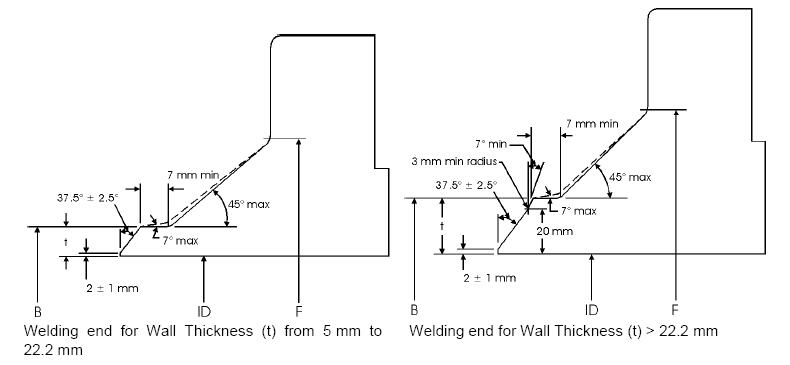

BS 4504 Standard Flange Facings Types, Welding Ends of neck flange

Weld Neck Flange – Welding Ends

Flange Facings – BS 4504

Why Purchase From Unichem Steel & Alloy Pvt. Ltd.

- Unichem Steel & Alloy Pvt. Ltd. strive for quality production of BS 4504 Flanges. We adequately test raw materials and confirm to ASTM, ASME, DIN, EN, JIS Standards to make the highest quality BS 4504 Flanges. BS 4504 Flanges is provided with 100% Radiography Test Report and Third Party Inspection or Buyer Inspection service is available on finished products.

- Value Added Services are provided such as Epoxy & FBE coating, Sandblasting, Hot dipped galvanizing, Electropolish or other special finishes, Threading, soldering, Custom shape cutting, fabrication services on BS 4504 Flanges.

- Unichem Steel & Alloy Pvt. Ltd. is an expert in manufacturing custom size BS 4504 Flanges with accurate dimensions and uniform wall thickness.

- We are presently equipped with modern manufacturing equipment and inspection tools such as Lathe Machines, Milling Machine, Heating & Annealing Furnaces, forging and deep drawing presses, machining, finishing, and testing facilities. In order to maintain reliability and quality of our EN 1092-1 BS 4504 Flange, MSS SP-44 BS 4504 Flanges, ISO Standard BS 4504 Flanges.

- As leading exporters and suppliers we keep a buffer stock of BS 4504 Flanges in all grades from ½” NB to 48” NB in Sch 10s, the 40s, 80s, 160s, XXS In order to meet the off-hand requirement of our clients.

- BS 4504 Flanges are packaged to ensure that there is no damage during transit. In the case of exports, products are packed in wooden cases. All BS 4504 Pipe Flanges are marked with Size, Lot No, Grade, Degree, and our trademark. On special requests we make custom marking on BS 4504 Flanges.

- Test Certificates: Raw Materials Certificate, Manufacturer Test Certificate as per EN 1092 / 3.1B, Third Party Inspection Report, 100% Radiography Test Report.

- No minimum quantity order limit. Get Market leading prices on all types of Industrial BS 4504 Flanges in India.

BS 4504 Flanges Material & Grades

| Stainless Steel BS 4504 Flange |

|---|

| ASTM / ASME A/SA 182: F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L. |

| Carbon Steel BS 4504 Flange |

| ASTM A105/A694/ A350 LF3/A350 LF2: F42, F46, F52, F56, F60, F65, F70 |

| Alloy Steel BS 4504 Flange |

| ASTM A182: F1, F5, F9, F11, F22, F91 |

| Duplex & Super Duplex Steel BS 4504 Flange |

| ASTM / ASME A/SA 182: F44, F45, F51, F53, F55, F60, F61. |

| Nickel Alloy BS 4504 Flange |

| ASTM / ASME SB 564 / 160 / 472: UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600(INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3) |

BS 4504 Flanges Manufacturing Standards

| ASME Standard | ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, UNI 2277/2278,, JIS, SABS1123, GOST-12820 |

|---|---|

| DIN Standard | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| EN Standard | EN1092 |

| ASTM A182 – ASME SA182 | Standard Specification for Wrought Austenitic SS Pipe Flanges |

| MSS SP-44 | Pipe Flange |

BS 4504 Flanges Type, Size, and Pressure Class

| Specification | Pressure Class | Size Range |

|---|---|---|

| ASME/ANSI B16.5 | 150 to 2500LBS 150 to 1500LBS |

26“ to 60″ 26“ to 48″ |

| ASME/ANSI B16.36 | 300 To 2500LBS | 1″ to 12″ |

| ASME/ANSI B16.47 | 75 to 300LBS 400, 600LBS 900LBS |

1/2“ to 12″ 26“ to 60″ 26“ to 48″ |

| BS 10 | TABLE-A, D, E, F, H, J, K, R, S, T | 15mm to 600mm |

| EN 1092-1 / DIN / BS 4504 Flanges | PN2.5 to PN16 PN25 PN40 PN63 PN100 PN160, PN250 PN320 PN400 |

10mm to 1800mm 10mm to 1000mm 10mm to 600mm 10mm to 400mm 10mm to 350mm 10mm to 300mm 10mm to 250mm 10mm to 200mm |

Ready Stock of BS 4504 Flanges in India

| BS 4504 Plate Flange | BS 4504 Welding Neck Flange | |

| BS 4504 Threaded Flange | BS 4504 Blind Flange | |

| BS 4504 Flange | BS 4504 PN 16 Dimensions | |

| BS 4504 PN 25 Dimensions | BS 4504 PN 40 Dimensions | |

BS 4504 Flange Dimensions Tolerance

|

Dimension |

Range |

Tolerance |

|

|---|---|---|---|

|

mm |

|||

|

Flange Facings |

Eccentricity of machined facing diameters |

< DN 100 |

1.0 |

|

> DN 100 |

2.0 |

||

|

a (type B facing height) |

2 mm |

+0, -1.0 |

|

|

3 mm |

+0, -2.0 |

||

|

4 mm |

+0, -3.0 |

||

|

5 mm |

+0, -4.0 |

||

|

6 mm |

+0, -5.0 |

||

|

b (type C and E facing height) |

All |

+0.5, -0 |

|

|

b (type G facing height) |

All |

+0, -0.5 |

|

|

b (type H facing height, outer) |

All |

+0.2, -0 |

|

|

c (type D and F facing height) |

All |

+0, -0.5 |

|

|

d (type H facing height, inner) |

All |

+0.5, -0 |

|

|

B and E (facing diameters) |

All |

+0, -0.5 |

|

|

C and D (facing diameters) |

All |

+0.5, -0 |

|

|

Surface Finish |

Facing types A, B, E and F |

All, turning |

Ra = 3.2 µm min 12.5 µm max |

|

All, other than turning |

Ra = 3.2 µm min 6.3 µm max |

||

|

Facing types C, D, G and H |

All |

Ra = 0.8 µm min 3.2 µm max |

|

|

Flange Drilling Details |

B (diameter of bolt circle) |

Bolt sizes M10 to M24 |

±0.9 |

|

Bolt sizes M27 to M45 |

±1.4 |

||

|

Centre to centre of adjacent bolt holes |

Bolt sizes M10 to M24 |

±0.45 |

|

|

Bolt sizes M27 to M45 |

±0.7 |

||

|

All |

A (outside diameter) |

< DN 150 |

±2.0 |

|

> DN 150 < DN 500 |

±3.0 |

||

|

> DN 500 < DN 1200 |

±5.0 |

||

|

> DN 1200 < DN 1800 |

±7.0 |

||

|

> DN 1800 |

±10.0 |

||

|

C (flange thickness, machined on both faces) |

< 18 mm thickness |

±1.0 |

|

|

> 18 mm < 50 mm thickness |

±1.0 |

||

|

> 50 mm thickness |

±1.0 |

||

|

C (flange thickness, machined on front face) |

< 18 mm thickness |

+2.0, -1.0 |

|

|

> 18 mm < 50 mm thickness |

+4.0, -1.5 |

||

|

> 50 mm thickness |

+7.0, -2.0 |

||

|

Weld Neck Flanges, Code 111 |

B (outside diameter of hub at welding end) |

< DN 125 |

+3.0, -0 |

|

> DN 125 < DN 1200 |

+4.5, -0 |

||

|

> DN 1200 |

+6.0, -0 |

||

|

F (hub diameter) |

< DN 50 |

+0, -2.0 |

|

|

> DN 50 < DN 150 |

+0, -4.0 |

||

|

> DN 150 < DN 300 |

+0, -6.0 |

||

|

> DN 300 < DN 600 |

+0, -8.0 |

||

|

> DN 600 < DN 1200 |

+0, -10.0 |

||

|

D (length through hub) |

< DN 80 |

±1.5 |

|

|

> DN 80 < DN 250 |

±2.0 |

||

|

> DN 250 |

±3.0 |

||

|

Slip on, Code 112 and Threaded,Code 113 |

E (slip on flange hub diameter)B (threaded flange hub diameter) |

< DN 50 |

+1.0, -0 |

|

> DN 50 < DN 150 |

+2.0, -0 |

||

|

> DN 150 < DN 300 |

+4.0, -.0 |

||

|

> DN 300 < DN 600 |

+8.0, -0 |

||

|

> DN 600 < DN 1200 |

+12.0, -0 |

||

|

> DN 1200 < DN 1800 |

+16.0, -0 |

||

|

> DN 1800 |

+20.0, -0 |

||

|

B (slip on bore diameter) |

< DN 100 |

+0.5, -0 |

|

|

> DN 100 < DN 400 |

+1.0, .0 |

||

|

> DN 400 < DN 600 |

+1.5, .0 |

||

|

> DN 600 |

+3.0, -0 |

||

|

D (length through hub) |

Same as Weld Neck D |

||

|

Blank Flanges, Code 105 |

B (flange thickness) |

Same as C for all other flanges |

|

|

C (unmachined centre portion) |

Maximum specified |

||

BS 4504 Flanges Applications and Uses

- Power Plant / Power Generation

- Fertilizers

- Oil & Gas

- Refineries

- Chemical Industry

- Pulp and Paper Industry

- Petrochemicals

- Engineering Project

- Environmental and Water Projects

- Boiler Manufacturers

- Pumps and Valves

- Cement Industries

- Aerospace Industry

- Nuclear Industry

- Construction

- Ship Building Companies

- Thermal Processing

- Pharma Industry

- Off-Shore Oil Drilling Companies

BS 4504 Flange Exporter

ASIA: Bangladesh, Cambodia, India, Indonesia, Japan, Malaysia, Maldives, Myanmar, Singapore, South Korea, Sri Lanka, Taiwan, Thailand, Vietnam.

AFRICA: Algeria, Angola, Egypt, Equatorial Guinea, Gabon, Libya, Nigeria, South Africa, Sudan, The Republic Of Congo.

MIDDLE EAST: Bahrain, Cyprus, Iran, Iraq, Jordan, Kuwait, Oman, Qatar, Saudi Arabia (KSA), Syria, Turkey, United Arab Emirates (UAE), Yemen.

NORTH AMERICA: Bahamas, Canada, Costa Rica, Denmark, Jamaica, Mexico, Panama, Puerto Rico, Trinidad And Tobago, USA.

SOUTH AMERICA: Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Venezuela.

BS 4504 Flange Supplier

Contact us to get a quick quote for BS 4504 Flanges.