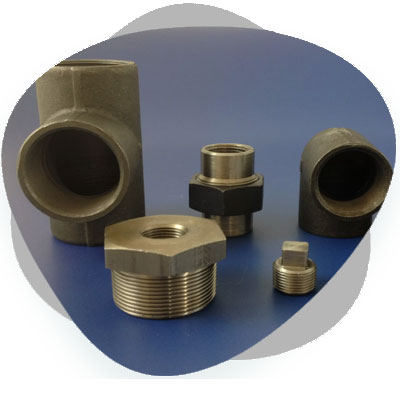

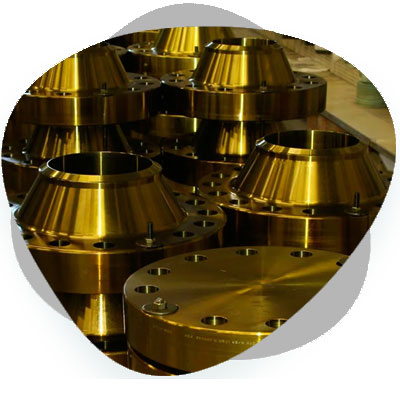

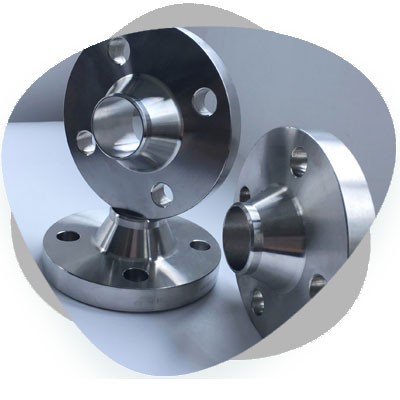

WE PRIDE OURSELVES AS BEING A PREMIER SUPPLIER OF INDUSTRIAL PIPE FITTINGS AND FLANGES

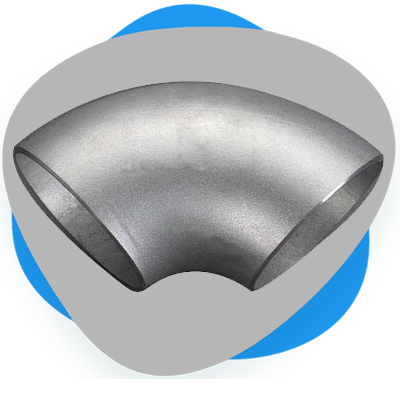

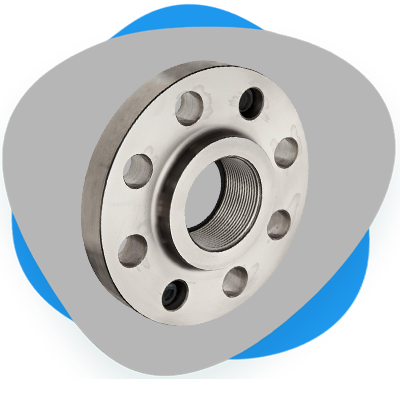

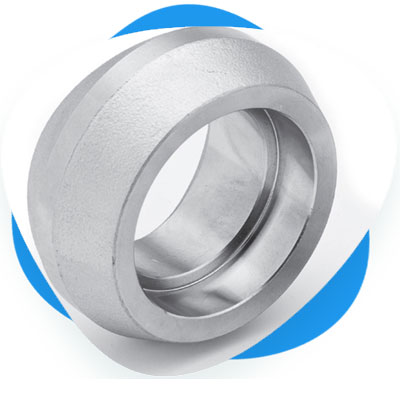

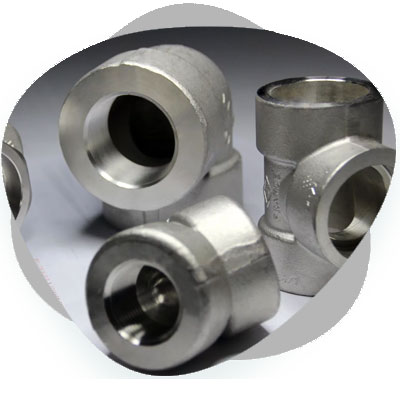

Being a leading supplier to an innumerous number of government and semi-government. bodies, major industries, big entrepreneurial ventures and their other adjuvants, Unichem Steel & Alloys Pvt. Ltd., is a Mumbai based pioneer of manufactures, suppliers stockists, and exporter in the evolving market of ferrous and Non-ferrous metals. We are a registered and reputed entity, operational across the country, with a primary focus on manufacturing and supplying all grades of Stainless Steel Seamless Pipe Fittings, Buttweld Fittings, Threaded Fittings, and Forged Socket Welds. Besides these, we also deal in all sorts of Industrial Flanges in the range of 304, 304L, 304H, 310s, 316, 316L, 316H, 316Ti, 317/317L, 321/321H, 347/347H, 904L.

Being in this field since the past two decades, we have successfully established ourselves as the most valued and trusted supplies and manufactures, sharing intricate relations and contacts with our consumers. Our field of expertise is also rooted in a wide range of dealings pertaining to raw materials in Ferrous and Non-ferrous metals, which predefine exceptional product quality, ideal for all our client requirements. What’s best about all of it is the range of prices we provide; affordable and reliable. Other product ventures that we specialise in include Special Bends, Pipe Fitting like Elbows, Caps, Reducers, Tees, and many more, associated with variety of metals such as Duplex & Super Duplex Steel, Stainless Steel, Carbon Steel, Alloy Steel, Nickle Alloys, among others.

What buyers has been saying about us.

They provided what they promised on a short notice, tight timeline, and with amazing precision. They exceeded my expectations and I highly recommend them – without a doubt.

-George Heropoulos

The firm is especially skilled at developing products (purchased Square Flange, Long Weld Neck Flange, & Ring Type Joint Flanges) that are economic to manufacture, yet offer high value.

-Tom Haag

There are a lot of companies who say they can, Unichem Steel and Alloy Pvt. Ltd. is one of a very few who really can. You can feel their internal energy, they are always excited about our projects.

-Randy Pyrtle

“We Export Steel Pipe Fittings and Flanges Worldwide To Below Mentioned Industries And Countries”

Chemical / Petrochemical

UAE, Saudi Arabia, Singapore

Food, Beverage, and Dairy

Qatar, South Africa, Australia.

Marine & dredging

Canada, Europe, Italy, US, Germany.

Oil and Gas

Kuwait, Malaysia, Oman, UK.

Power Generation

Bahrain, Nigeria, Algeria, Morocco.

Pulp and Paper

Ghana, Egypt, Finland, France.

Manufacturing Products - Available in Stock

Stainless Steel is a corrosion-resistant alloy of chromium, iron, and, in some cases, nickel and other metals. Infinitely and Completely recyclable, stainless steel is the “green material” par excellence. In fact, within the construction sector, the recovery rate of stainless steel is close to 100%. SS are steels containing less than 1.2% carbon, at least 10.5% chromium, and other alloying elements. Stainless steel’s mechanical properties and corrosion resistance can be further enhanced by adding other elements, such as molybdenum, nickel, niobium, titanium, manganese, etc.

Applications

| Architecture, Building & Construction | Heavy Engineering & Machinery | Food, Beverage & Process Plant |

| Offshore engineering | Drying Plant | Beer Bottling Machines |

| Paper Making Machinery | Load-Bearing Structures | Railways & Underground Railways |

| Catwalks | Packaging Machinery | Facades |

| Mining | Bus & Coach Chassis | Acoustic Structures |

Carbon Steel can be divided into three main types: Low carbon steel (also known as mild steel); Medium carbon steel; and High carbon steel. Mild Steel: Generally having 0.04% to 0.30% carbon content. Depending on the required properties, other elements are increased or added in carbon steel. Medium Carbon Steel: Generally has a carbon of 0.31% to 0.60%, and a manganese content ranging from .060% to 1.65%. It is stronger as compared to low carbon steel, and it is more difficult to weld, form, and cut. Medium carbon steels are quite often hardened and tempered using heat treatment. High Carbon Steel: Also known as “carbon tool steel” it generally has a carbon between 0.61% and 1.50%. High carbon steel is very difficult to bend, cut, and weld. Once heat treated it becomes extremely hard and brittle.

Selecting carbon steel to have several advantages over traditional steel, such as increasing strength. The use of carbon makes iron — or steel — stronger by shuffling around its crystal lattice. While carbon steel can still break and stress under pressure, it’s less likely to occur than with other types of steel. This makes carbon steel particularly effective in applications where strength is needed.

Alloy Steel is made by combining CS with one or several alloying elements, such as silicon, manganese, titanium, nickel, chromium, copper, and aluminum. These metals are added to produce specific properties that are not found in regular carbon steel. The elements are added in varying proportions or combinations by making the material take on different aspects such as increased corrosion resistance, increased strength, increased hardness, improved formability (ductility); the weldability can also change. most common alloying elements are Manganese, Chromium, Vanadium, Nickel, and Tungsten.

There are mainly two types of alloy steel – high-alloy steel and low-alloy steel. the proportion and composition of alloying elements determine the various properties of alloy steel. high-alloy steels have more than 8% alloying elements whereas Low-alloy steels are the ones that have up to 8% alloying elements.

Hastelloy is one of the best nickel-based steel alloys that show high resistance to corrosion. In addition to outstanding resistance to all manner of pitting and cracking, pipe fittings and flanges made from Hastelloy metal blends tend to find good use across a wide range of chemical applications that might otherwise oxidize the metal. The B-3 alloy possesses outstanding resistance to non-oxidizing acids, such as hydrochloric acid and sulfuric acid. C-22 alloy is particularly resistant to pitting and crevice corrosion; it has been used extensively to protect against the most corrosive FGD systems and the most sophisticated pharmaceutical reaction vessels.

Hastelloy applications:

- Oil & Gas

- Chemical Process

- Petrochemical

- Pharmaceutical

- Geothermal

- Mining

- Utilities

- Nuclear Power

- Solar Power

- Sea Water

- Water Desalination

- LNG (Liquefied Natural Gas)

- Biomass

Inconel® is a material that is specifically optimized for some of the toughest use conditions to be found in manufacturing. Even compared to stainless steel, Inconel® has an incredibly high tolerance for extreme heat and doesn’t lose as much tensile strength at 2,000°F as most varieties of steel.

Inconel 600 is the very first Inconel alloy brought to market. The original target application of Inconel was far humbler: milk cans, but it now finds use in nuclear reactors. Based upon a chemical composition of >72% nickel, with less than 10% iron and up to 17% chromium, it was one of the first alloys to perform well at elevated temperatures of up to 600degC.

Monel is commonly used in applications with highly corrosive conditions. Small additions of aluminum and titanium form an alloy (K-500) with the same corrosion resistance. However, with much greater strength due to gamma prime formation during aging, Monel is typically much more expensive than stainless steel.

What are the Characteristics of Monel?

- Good resistance to acids such as hydrofluoric and sulfuric acid

- Highly resistant to alkalis

- Malleable

- Highly corrosion resistant

- Stronger than steel

Nickel-based alloys offer good performance at higher temperatures. The melting temperature of nickel is 1453degC, which is far higher than metals such as copper (1084degC) and aluminium (660degC). The ability to operate at elevated temperatures though is not only linked to metals melting temperature, otherwise iron (1150degC) or steel (1400degC) would be more widely used.

Nickel has outstanding physical and chemical properties, which make it essential in hundreds of thousands of products. Its biggest use is in alloying – particularly with chromium and other metals to produce stainless and heat-resisting steels.

- HIGH MELTING POINT 1453°C

- RESISTS CORROSION AND OXIDATION

- HIGHLY DUCTILE

- ALLOYS READILY

- MAGNETIC AT ROOM TEMPERATURE

- CAN BE DEPOSITED BY ELECTROPLATING

- HAS CATALYTIC PROPERTIES

- CAN BE FULLY RECYCLED

Copper-nickel (also known as cupronickel) alloys are widely used for marine applications due to their excellent resistance to seawater corrosion, low macrofouling rates, and good fabricability. They have provided reliable service for decades while offering effective solutions to today’s technological challenges.

Applications by Industry

Marine: Guidelines for Seawater System Design and Operation are presented; Sections cover Cu-Ni in Desalination Plants, Seawater System Components are detailed; Shipbuilding and Ship Repair, Offshore Oil and Gas, Power Generation, Boat Hulls, and Marine Antimicrobial applications.

Non-Marine: Coinage; Brake Tubing.

Duplex stainless steel are extremely corrosion resistant, work hardenable alloys. Their microstructures consist of a mixture of austenite and ferrite phases. As a result, duplex stainless steels display properties characteristic of both austenitic and ferritic stainless steels.

Duplex stainless steel Applications

- Chemical processing, transport and storage

- Oil and gas exploration and offshore rigs

- Oil and gas refining

- Marine environments

- Pollution control equipment

- Pulp & paper manufacturing

- Chemical process plant

Super Duplex Stainless Steel is known to have better stress corrosion, mechanical properties and cracking resistance than any other type of steel. Super Duplex is an austenitic-ferritic iron chromium – nickel alloy with molybdenum addition. It has good resistance to pitting and a very good tensile strength and high resistance to stress corrosion cracking at moderate temperatures, compared to that of conventional austenitic stainless steels.

Benefits of Super Duplex

- Improved corrosion resistance in comparison to Duplex

- Greater tensile and yield strength

- Good ductility and toughness

- Good stress corrosion cracking resistance (SSC)

- Opportunity for purchases to reduce their material costs without compromising on quality

The element titanium, with chemical abbreviation Ti, has the atomic number 22 and is a member of the transition metals. It appears as a highly lustrous, silver-colored metal. A great deal can be said about titanium simply from its name, the root of which is ‘Titan’. In Greek mythology, the Titans were known as a group of very strong and resilient deities (or supernatural beings).

- Titanium is twice as Strong as Aluminum

- Titanium Naturally Resistant to Corrosion

- Titanium Doesn’t Occur Naturally

- Titanium is used for Medical Implants

- Only 0.63% of the Earth’s Crust Is Titanium

- Titanium has a High Melting Point

Alloy 20 is a low-carbon, niobium-stabilized austenitic nickel/iron/chromium alloy with additions of molybdenum and copper. It exhibits exceptional corrosion resistance in chemical environments containing phosphoric acid, nitric acid, chlorides and sulfuric acid. It also has good mechanical properties at both ambient and elevated temperatures.

Designations that are equivalent to alloy 20 include the following:

- ASME SB-462 – SB-464

- ASTM B 462 – B 464

- ASTM B 472 – B 474

- ASTM B 468

- ASTM B 751

- ASME SB-468

Alloy 20 Applications:

- Production of plastics and synthetic fibers

- Chemical and petroleum processing equipment

- Mixing tanks

- Heat exchangers

- Process piping

AISI or SAE 4130 is a low-alloy steel containing molybdenum and chromium as strengthening agents. The steel has good toughness and strength, machinability and weldability. This low-alloy steel finds many applications as forgings in the oil and gas and aerospace industries, as well as in the agricultural, automotive, and defense industries.

Below is an exact chemical breakdown of 4130 steel, with tolerances:

- 0.28 – 0.33% Carbon

- 0.8 – 1.1% Chromium

- 0.7 – 0.9% Manganese

- 0.15 – 0.25% Molybdenum

- ≤ 0.035% Phosphorus

- 0.15 – 0.35% Silicon

- ≤ 0.04% Sulphur

SS grade 254 SMO is a very high end austenitic stainless steel. It is designed with a combination of impact toughness resistance to chloride stress corrosion cracking, and pitting and crevice corrosion with the strength that is twice that of the SS Grade 300 series.

SMO 254 Applications:

- Saltwater handling

- Tall oil distillation columns

- Flue gas desulfurization scrubbers

- Process equipment in chemical industry

- Flue-gas cleaning

- Components used in petroleum production

- Food processing equipment

- Desalination

- Bleaching equipment in the pulp and paper industry

- Heat exchangers